Our Products

Teflon Fixture

A Teflon fixture typically refers to a fixture or component made from Teflon (polytetrafluoroethylene or PTFE) material. Teflon is known for its non-stick properties, resistance to heat and chemicals, and low friction coefficient, making it suitable for various industrial applications. Teflon fixtures can be found in automotive components, such as seals and gaskets, where resistance to heat, chemicals, and friction is crucial. Teflon fixtures are used in aerospace applications due to their lightweight nature, resistance to extreme temperatures, and low friction properties. Manufacturers specializing in Teflon fixtures typically have expertise in machining or molding Teflon materials to create custom components tailored to specific industrial needs. These fixtures may include gaskets, seals, bearings, bushings, valves, and various other precision components.

Coating Fixture

It seems like you're referring to a "coating fixture." A coating fixture is a specialized tool or device used in various industries, particularly in manufacturing and surface treatment processes, to hold or secure items during the application of coatings such as paint, powder coating, plating, or other surface treatments. These are custom-designed tools used to hold parts or components in place during the coating process. They ensure proper positioning and prevent movement or distortion of the item being coated. When selecting or designing a coating fixture, factors such as the size and shape of the parts, the type of coating being applied, production volume, and process requirements need to be considered. Well-designed coating fixtures contribute to consistent coating quality, increased efficiency, and reduced material waste in manufacturing processes.

Printing Fixtures

Printing fixtures are tools or devices used in the printing industry to hold substrates (materials being printed on) in place during the printing process. They ensure accurate and consistent positioning of the substrate relative to the printing equipment, which is crucial for achieving high-quality prints. Printing plates are fixtures used in traditional printing methods like offset printing and flexography. These plates are mounted onto printing presses and hold the image or design to be printed. Custom jigs and fixtures are designed to hold specific substrates or products in place during printing. They ensure consistent positioning and registration of multiple items for batch printing. Printing fixtures play a critical role in achieving precise registration, consistent print quality, and high production efficiency in various printing applications. They are designed to accommodate different types of substrates, printing methods, and production requirements.

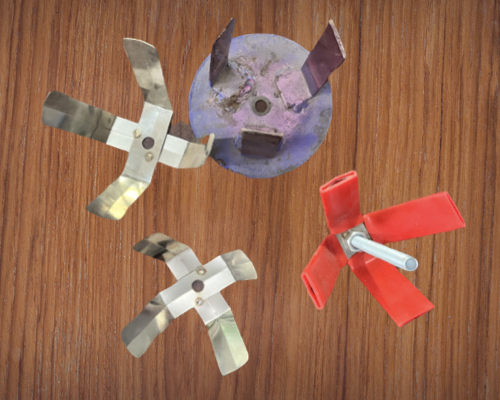

Coating Jigs

"Coating jigs" seems to be a typographical error, but it appears to be referring to "coating jigs" used in various industrial processes. Coating jigs are fixtures or tools designed to hold workpieces securely during coating operations. They ensure proper positioning and stability of the items being coated, which is essential for achieving uniform coating thickness and quality. These jigs are used to hold parts or components in place during spray coating processes such as painting or powder coating. They may feature adjustable clamps, racks, or holders to accommodate different shapes and sizes of workpieces. Coating jigs are typically custom-designed to suit specific coating applications and workpiece requirements. They play a crucial role in ensuring efficiency, consistency, and quality in coating operations across various industries.

Coating Caps

"Coating caps" seems to be a term that might refer to "coating caps" or "coating caps for protection." These are specialized caps or covers used to protect specific areas of an object from coatings, such as paint, spray, or plating, during manufacturing or finishing processes. They ensure that only the desired areas of the object are coated while leaving the rest unaffected. These caps are used to cover and protect threaded or cylindrical surfaces, such as bolts, studs, or fittings, from coatings. They come in various sizes and designs to fit different thread sizes and shapes. Coating caps are essential tools in industries such as automotive, aerospace, electronics, and manufacturing, where precise and controlled coating application is necessary to meet quality standards and specifications. They help to streamline production processes, minimize waste, and ensure consistent results in coating applications.

Aluminum Universal Fixture

An "Aluminum Universal Fixture" could refer to a versatile fixture or tool made primarily from aluminum that is designed to hold various workpieces in place for machining, assembly, inspection, or other industrial processes. These fixtures are often customizable and adaptable to different shapes, sizes, and types of workpieces, making them suitable for a wide range of applications. The fixture is primarily constructed from aluminum or aluminum alloy, known for its lightweight yet sturdy properties. Aluminum is often preferred for its corrosion resistance, durability, and ease of machining. Aluminum universal fixtures find applications in industries such as manufacturing, automotive, aerospace, electronics, and prototyping, where efficient and adaptable workholding solutions are required to optimize production processes and ensure consistent quality.

Jar Fixture

If you want to produce interchangeable parts, you will need to use a jig, fixture, or both depending on the operation. Human error is vastly limited. So components can be machined quickly with high levels of accuracy , which reduces costs. Jigs are a type of fixture that guides and supports a tool, Whereas A fixture is a work-holding or support device used in the manufacturing industry. Fixtures are used to securely locate and support the work, ensuring that all parts produced using the fixture will maintain conformity and interchangeability.

Printing Machine

"Printing Machine" could refer to a machine used in the printing industry specifically designed for printing on fixtures or workholding devices used in manufacturing processes. These machines are crucial for adding identification marks, branding, instructions, or other relevant information directly onto fixtures, ensuring traceability and compliance with quality standards. User-friendly interfaces and intuitive controls make it easier for operators to set up and operate the machine. Additionally, features that simplify maintenance tasks, such as self-cleaning mechanisms or easy access to components, can minimize downtime and optimize machine performance. By incorporating these features, a fixtures printing machine can significantly streamline the manufacturing process by efficiently adding essential information directly onto fixtures, contributing to improved traceability, quality control, and overall production efficiency. We work all types of glass, bottle, round, half round, flat printing.

Laser Marking

Laser marking is a non-contact marking method that uses a laser beam to create permanent marks on a variety of materials. Unlike traditional marking methods such as engraving or printing, laser marking does not involve the use of inks, dyes, or tool bits, making it a clean and environmentally friendly process. Instead, the laser beam interacts with the surface of the material, causing a change in its appearance through processes such as oxidation, ablation, or annealing. Laser marking offers several advantages over traditional marking methods, including high speed, non-contact operation, permanent marks, minimal material distortion, and the ability to mark complex shapes and small features with high precision. Overall, laser marking is a versatile and efficient marking solution that has become increasingly popular across various industries due to its ability to produce high-quality marks with speed, precision, and versatility.